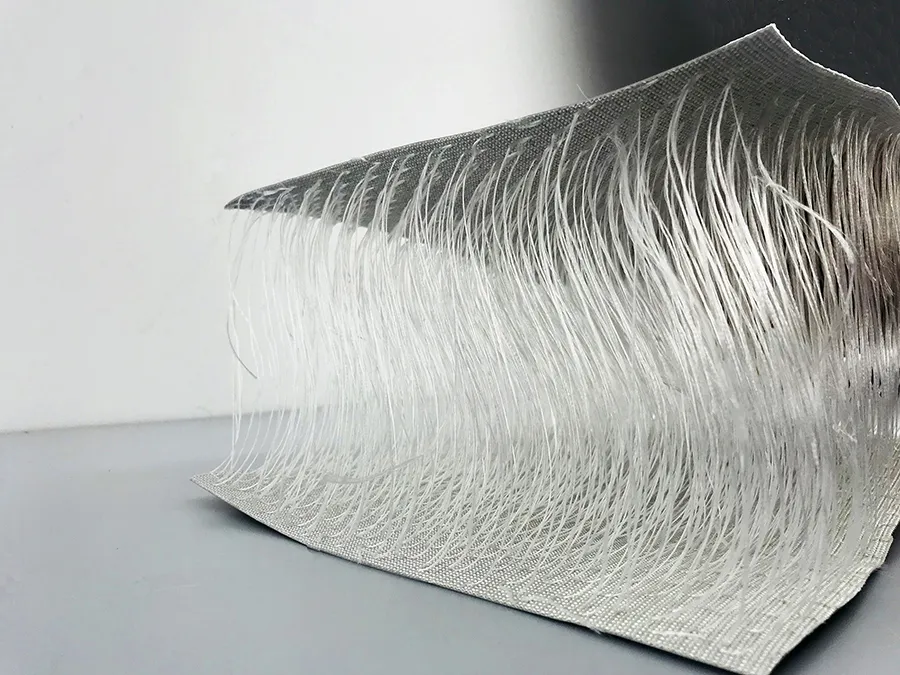

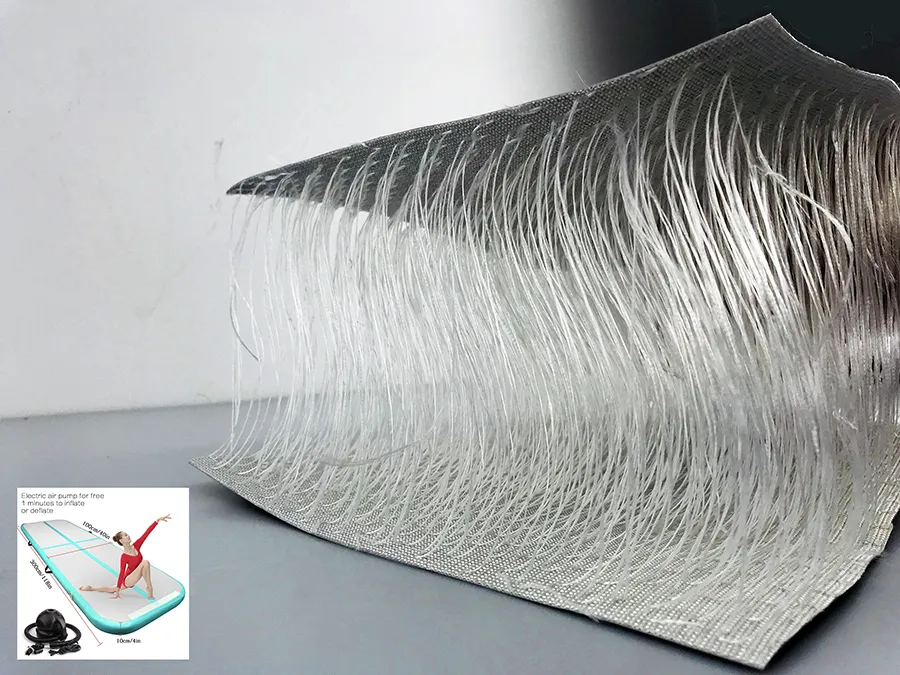

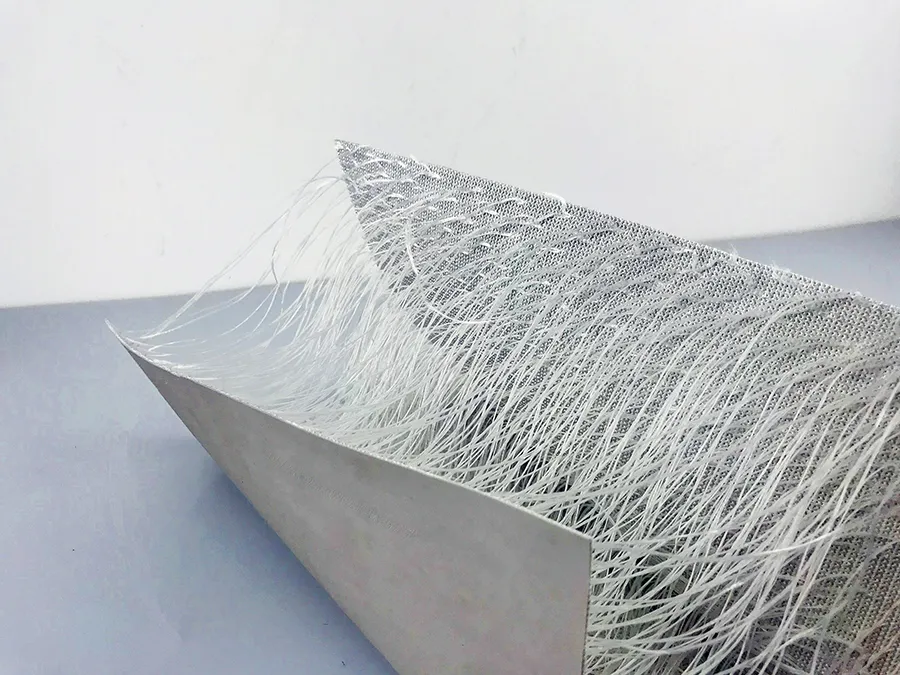

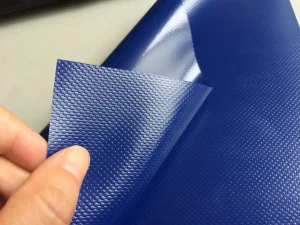

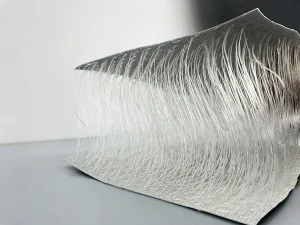

Double-wall fabric is becoming increasingly popular with applications such as inflatables, gym mats and more. It’s a coated nylon joined by thousands of vertical fibers that are uniform in size. When welded into a desired shape and pressurized with air, it is transformed into a strong, hard surface.

Woven double-wall fabric benefits:

Double-wall fabrics can be used to manufacture inflatable products that are lightweight and easy to transport yet are rigid and structurally stable.

The breaking strength of equally long pile yarns can reach more than 1Mpa (10 atm, 145PSI), so it is very safe to use, and not worry about the fracture problem of pile yarns completely. The routine use pressure of DWF is under 20 PSI. With a special PVC airtight coated, the adhesion strength of KOP DWF can reach more than 150 N/5CM, so not worry about the ply separation or burst problem.

Product Characteristics

- Double wall fabric with drop stitches in the middle, supply 3D stability region

- Drop stitches give supports to every spot of the surface, avoiding depressed deformation.

- Favorable adhesion during the welding process

- Rock-hard rigidity, recommended pressure 20-30 PSI.

Application

Products produced using double-wall fabrics include:

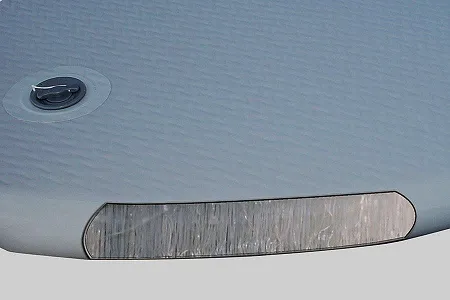

Inflatable boat bottom

Paddle board

Athletic mattress and more

Potable temporary soundproof wall

With the characteristics of this material combined with the welding process, the possibilities are endless.